How It's Done

To ensure the most effective partitioning of a building, the walls and floors of compartments must have a fire-resistance degree corresponding to the type of building (please refer to your respective countries’ building regulations).

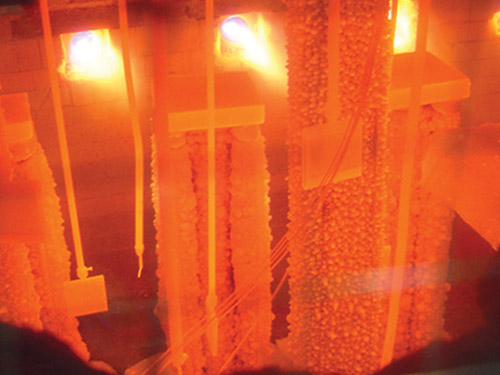

It is important to note that these compartments are equipped and overlapped by multiple elements: doors, hatches, partitions, plastic, metal tubes, cables, etc. All fireproofing caulks around these elements must therefore make it possible to reconstruct the fire-resistance degree of the wall by providing fire resistance at least equal to that of the building structure.

It is via this method that we can achieve a powerful subdivision to slow the spread of fire.

Let’s take the below example to explain the need of effective compartmentalisation:

We are located below a room measuring six metres long, six metres wide and six metres high. A fire takes place in the next room. If there is a hole the size of a pencil in the wall, smoke from the next room will fill our room in record time. After only 3 minutes and 40 seconds, the smoke will be so thick that we will not be able to distinguish hands in front of us, giving us visibility distance of less than 40 cm.

Flames, heat, and smoke have a formidable propagation capacity and are difficult to control. The purpose of compartmentalisation is to stop their progression via passive fire solutions that are adapted to comply with regulations.

By ensuring effective compartmentalisation, the propagation of fire and smoke from one room to another will be contained for a period of 120 minutes up to 240 minutes. This allows for evacuation to take place and for the intervention of emergency services.

This article has been contributed by the fire protection specialists at CPG Europe.

Passive Fire Protection Specialist

Nullifire has been at the forefront of the passive fire protection market for over 45 years.

At Nullifire we have always strived to provide fire protection systems that will, ultimately, perform in a fire situation. As such we have been at the forefront of developing several waterborne intumescent systems over the years.

All of Nullifire’s systems, be they intumescent coating for structural steel protection, or the comprehensive fire stopping range, have been fully tested to relevant British, European, Australian and Japanese test standards allowing them to be used in the whole of Asia Pacific.

Our expert team are on hand to help you in any current or upcoming project you may have, do get in touch with the team

Fire Protection

Different Types Of Intumescent Coatings And Their Benefits

Fire Protection

Different Types Of Intumescent Coatings And Their Benefits

Fire Protection

Understanding Firestopping and Fire Protection

Fire Protection

Understanding Firestopping and Fire Protection

Fire Protection

What is the difference between "Reaction to Fire" vs "Resistance to Fire"?

Fire Protection

What is the difference between "Reaction to Fire" vs "Resistance to Fire"?