Balancing Cost-Effectiveness and Environmental Responsibility in TPO Roofing

TPO membranes have gained popularity since their introduction in the 90s for flat and low-slope commercial roofs. They offer energy efficiency, durability, cost-effectiveness, ease of installation, environmental benefits, and design flexibility.

Project site in Malaysia, 2024

Project site in Malaysia, 2024

Understanding TPO Roofing

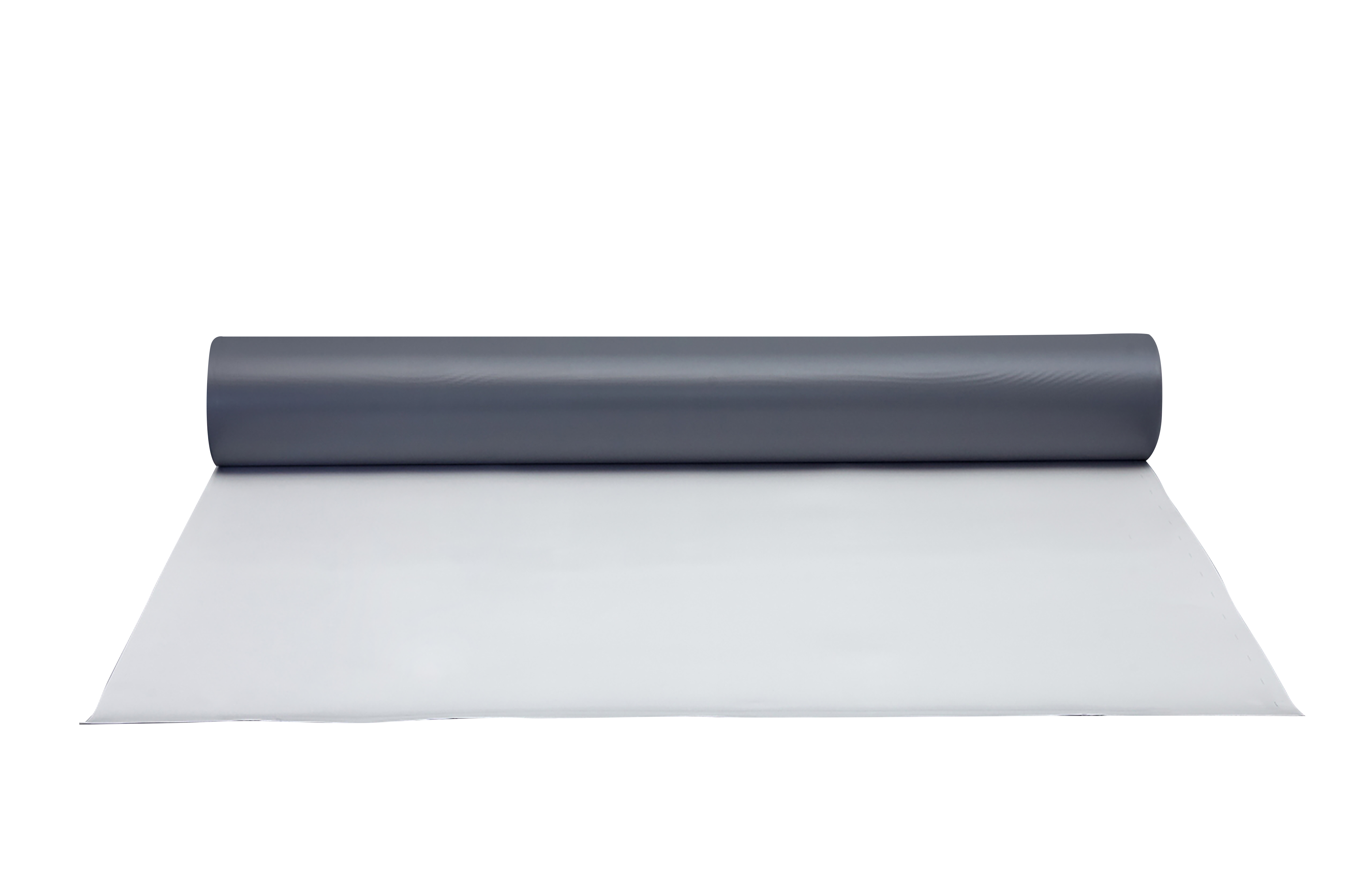

TPO (Thermoplastic Polyolefin) is a single-ply synthetic roofing membrane composed of a TPO polymer base, a polyester-reinforced scrim, and a TPO compounded top ply. It combines the flexibility of rubber with the heat-weldability of thermoplastics, making it suitable for commercial and industrial roofs.

TPO membranes are commonly available in reflective white or light-coloured options with a high Solar Reflectance Index (SRI), minimizing heat absorption and enhancing energy efficiency, particularly in warm climates.

Sustainability and Environmental Impact

TPO membranes are an environmentally friendly roofing solution, free from harmful substances like chlorofluorocarbons (CFCs) and halogens, while also requiring less energy to produce. Their sustainability is closely tied to durability, with high-quality TPO membranes lasting between 25 and 30 years. Furthermore, aged TPO membranes can be recoated with SolarGard 6083 and AlphaGuard Bio, extending their service life by up to 25 years.

TPO is also well-suited for green, solar, and blue roofs, further contributing to a building’s overall environmental efficiency.

Simplified Installation Process

Project site in Vietnam, 2023

Project site in Vietnam, 2023

TPO membranes come in various sizes and thicknesses for flexible design and easy installation. They can be fully adhered, ballasted, or mechanically attached. Seams between sheets are hot-air welded for strong, watertight joints. Installation is flame-free, improving safety.

For refurbishment projects, TPO can be installed over existing roofs, reducing waste from tear-offs.

Maintenance and Repair Considerations

TPO membranes require minimal maintenance. Regular inspections help identify issues early. While they will accumulate dirt over time, reducing reflectivity, periodic cleaning restores their performance. TPO membranes are easy to repair, even after years of exposure.

Why Choose TREMguard LLM TPO?

TREMguard LLM TPO meets ASTM D6878 standards, ensuring superior performance. It features ethylene propylene rubber within a polypropylene thermoplastic matrix, providing durability, flexibility, and resistance to UV, ozone, and heat degradation.

TREMguard LLM TPO is compatible with green roofs and PV installations, thanks to its root resistance, high reflectivity, and weather resistance. It is available in various thicknesses, with wide rolls for fast coverage.

With a stable formulation and antioxidants, TREMguard LLM TPO remains easy to weld and repair after years of service. Since it contains no halogens or heavy metals, it is also recyclable, promoting sustainability in roofing systems.

** ASTM D6878 is the Standard Specification for Thermoplastic Polyolefin-Based Sheet Roofing.

Learn more about the step-by-step installation and watch the video here.

For regular updates on products, projects and technical insights, join our community on LinkedIn and connect with like-minded professionals.

Waterproofing and Roofing

Popular Types of Commercial Roofs and Waterproofing Systems

Waterproofing and Roofing

Popular Types of Commercial Roofs and Waterproofing Systems

Waterproofing and Roofing

Common Problems Associated with Poor Waterproofing

Waterproofing and Roofing

Common Problems Associated with Poor Waterproofing

Waterproofing and Roofing

Step-by-Step Installation of the TREMguard LLM Fully Bonded System

Waterproofing and Roofing

Step-by-Step Installation of the TREMguard LLM Fully Bonded System